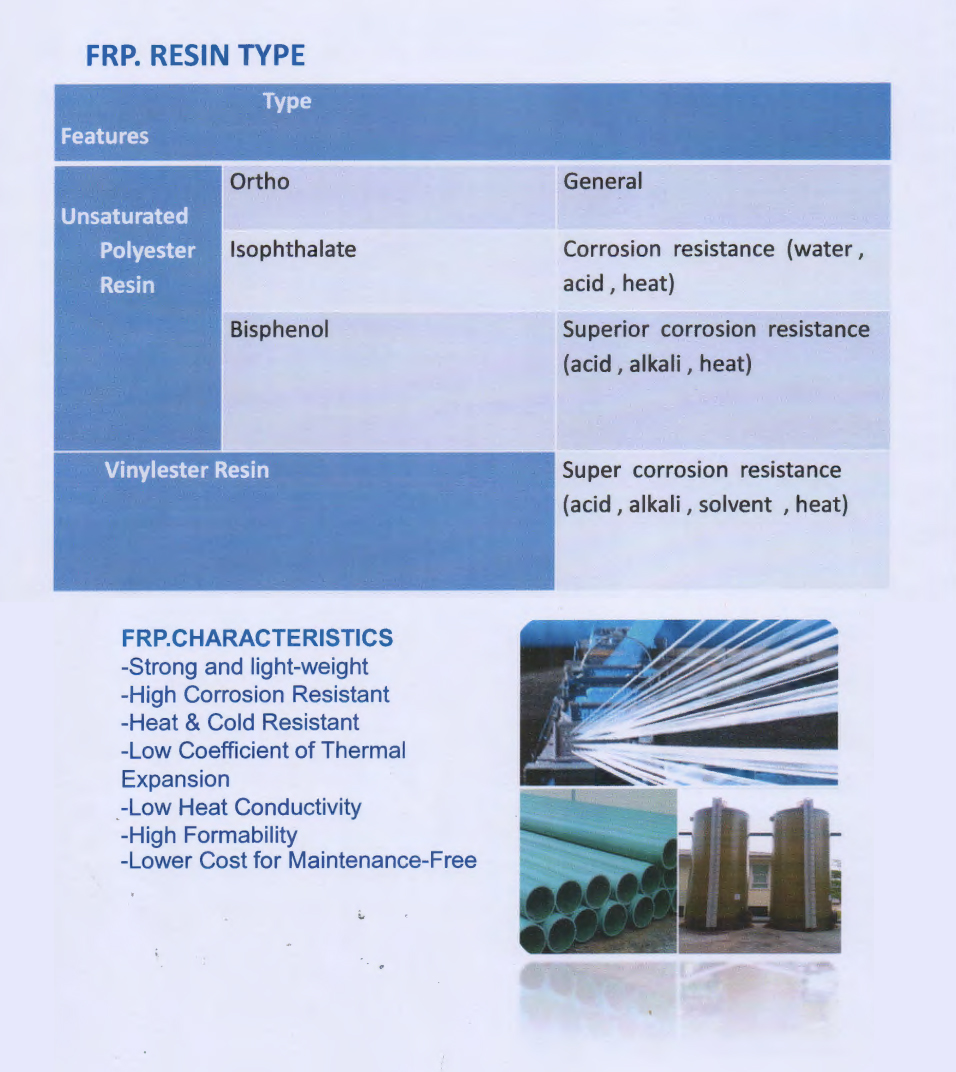

An abbreviation of Fiberglass Reinforced Plastics indicates the specific type of plastic, which is reinforced with fibergalss.

FRP. is a compound meterial of special matrix which is hightly waterproof, heat resistant and anti-chemical agent, and fiberglass which high tensile strength. This function is like Reinforced Concrete, strengthened with reinforcing steel bars.

No other material can provide such a compound chareacteristic of strong corrosion resistance and strength.

FRP. has been used for bath-tub, sewage tank, and other housing materials of corrugated sheet and panels. Recently, of its unique characteristics, high corrosion resistance, chemecal agent resistance, strong mechanical properties, durabiliy and light-weight, demand for FRP. continues to expand in various applications, thus for industrial plant facilities as a substitute of steels.

.